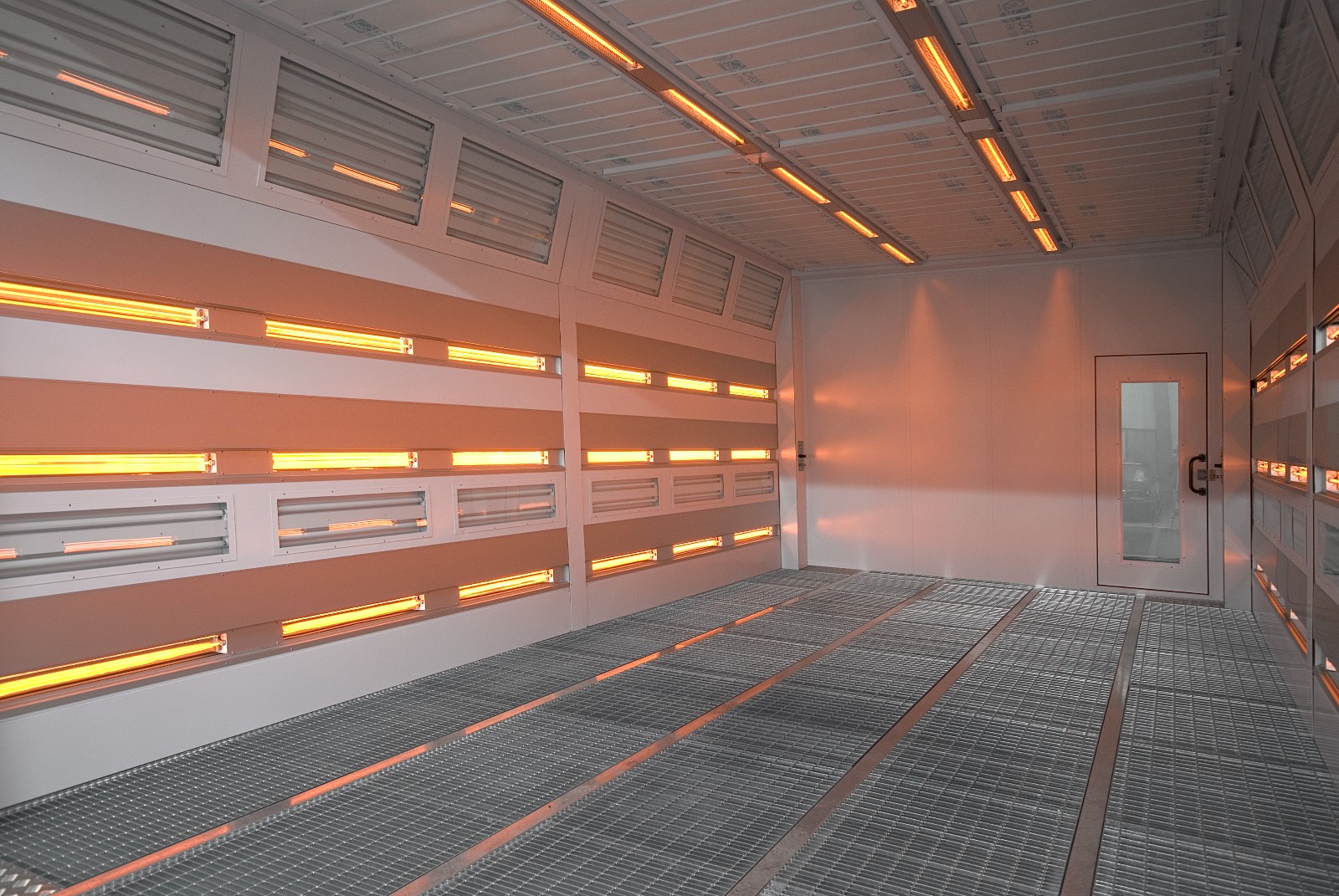

Raptor

Fully Electric Infrared Spray Booths

Raptor is the most energy efficient and advanced infrared spray booth available. It uses a fully-electric heating system and Infrared curing coupled with high airflows and advanced control system to provide the lowest running costs and fastest production times. Raptor is available with two different infrared lamp configurations, the setting system, stainless steel finish and 4-leaf fully glazed entrance doors.

Raptor spray booths save time and money compared to a traditional Oil or Gas fired spraybooth for every job, cutting curing time and energy consumption significantly, all whilst providing top of the range airflows. Being fully electric, Raptor allows you to significantly reduce your carbon emissions.

The Setting System splits the booth into discrete zones, diverting all the air to just one zone of the cabin, significantly reducing running costs even further for smaller jobs such as when you are painting a wing.

Eurotecno also supply a large range of Automotive spray booths with traditional oil and gas fired heating and curing and an IR-Kit which can convert any Eurotecno automotive booth and many third party booths into Hybrid booths with infrared curing.

Raptor spray booths are fully compatible with Electric Vehicles as they can be cured with infrared without damaging or affecting the batteries unlike traditional hot air curing that can overheat the batteries.

Raptor is a no-compromise spray booth. Performance exceeds that of a traditional booth in every way, with increased efficiency and superior curing.

Energy Efficient

The lowest running costs available

No fossil fuels

Fully electric infrared spray booth

Saves Time

Cuts curing time dramatically